With the rapid development of the pharmaceutical industry, it also drives the continuous transformation and upgrading of the pharmaceutical cold chain logistics. In the context of the normalization of epidemic prevention and control, the production and supply of drugs, instruments and other materials for COVID-19 prevention and control have put forward higher requirements for China’s pharmaceutical cold chain logistics. The construction of the storage system is an important link in the pharmaceutical cold chain logistics. Affected by many factors such as policies and markets, the construction of the pharmaceutical storage system presents a development trend of flexibility, automation and intelligence.

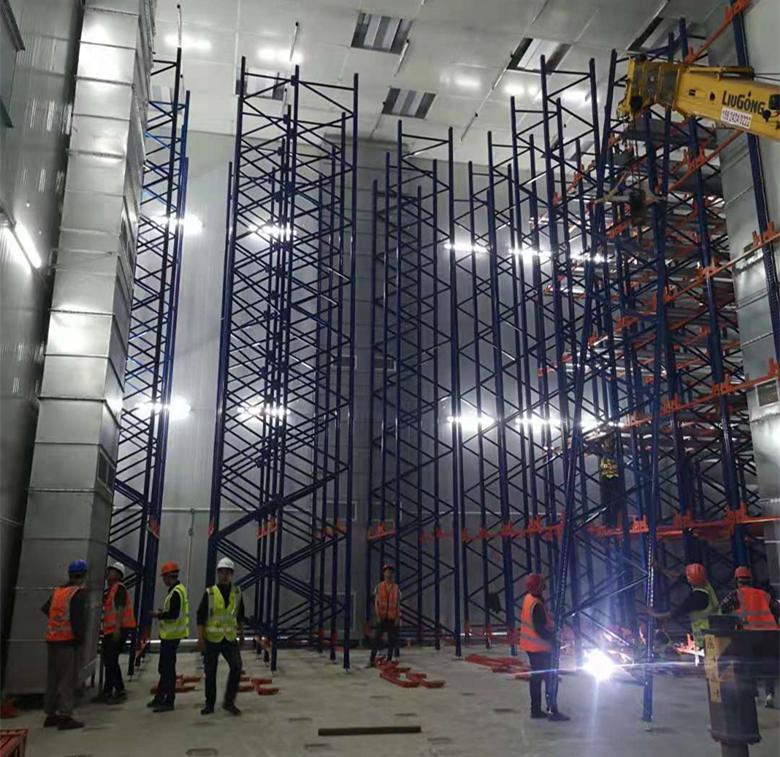

In May 2021, OTL Systems reached a cooperation with a pharmaceutical enterprise to be responsible for the design, production and installation of its vaccine cold storage shelf system. The shelf type of the project is the pallet shelf system of the four-way shuttle vehicle. The shelf height is 11.5 meters and the pallet cargo space is more than 6000.

The normal construction time for a project of this size is around two months, but due to the urgent needs of the client, the lead time of the project was reduced to 30 days. Due to the short construction period, heavy tasks and high quality requirements, OTL Systems has gathered various departments, including design, production, shipping and installation, to jointly escort the project and ensure the smooth delivery of the project on schedule.

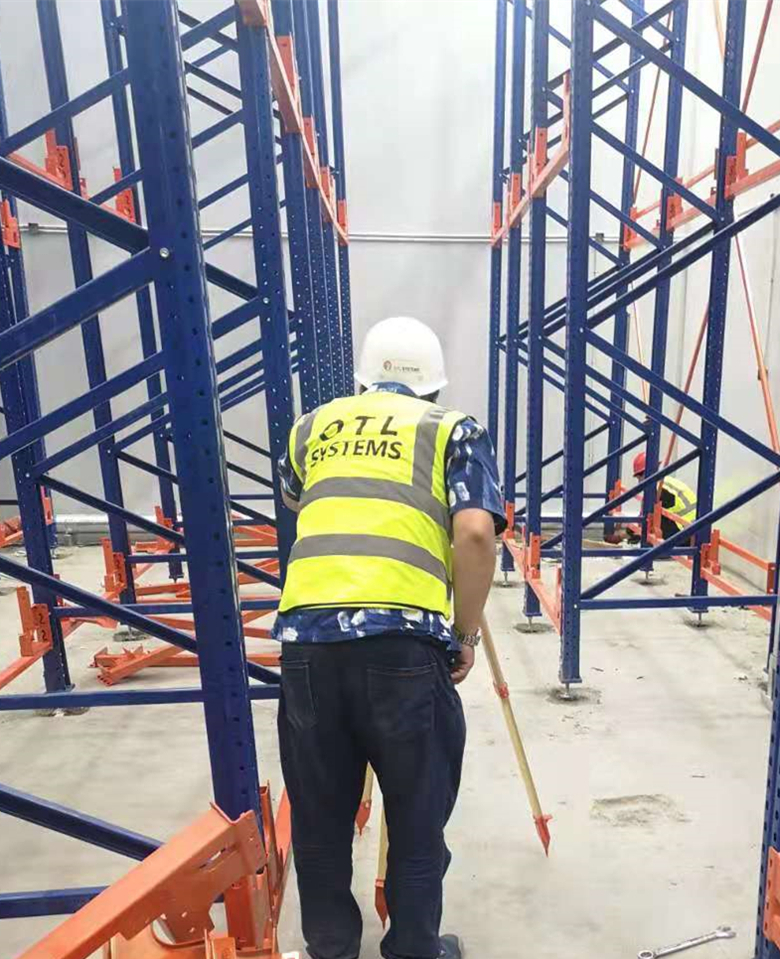

The project construction site has narrow space, many cross-working areas (weak current, fire protection, network security and other projects are simultaneously constructed), limited space for shelf assembly and hoisting, which brings great challenges to the progress control of the installation work. At the start of the project, OTL Systems has established a strong project management team, selected elite installation team, equipped with a number of experienced installation guidance, formulated feasible construction period guarantee measures, arranged 24-hour shift uninterrupted construction, working overtime, burning the midnight oil, the project is now in full swing.

Due to the use of shuttle vehicles, AGVs, storage robots and other automatic equipment in this project, the production and installation precision deviation control requirements of shelves are very high. OTL Systems has introduced advanced manufacturing equipment to produce ultra-high precision shelves, and combined with more than 20 years of storage shelf design and installation experience, to ensure the perfect fit of the shelf system and automation equipment.

With the team’s efforts, the project is expected to be completed ahead of schedule. Working hard for 30 days to maintain the time limit, not only shows the professional and efficient team of OTL Systems, but also highlights the social mission of OTL Systems, and makes a contribution to protecting human health and defeating the epidemic.

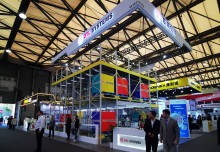

OTL Systems has been deeply engaged in the field of storage equipment for more than 20 years, during which it has participated in the construction of many warehouses in the pharmaceutical industry. According to customers’ storage needs, it has built personalized storage shelf system for customers, and accumulated rich experience in the industry. In the future, OTL Systems will continue to adhere to the concept of “product first” and “customer first”, strive for perfection, deeply plow the original competitive industries, expand emerging markets, and customize professional and efficient warehousing system solutions for more customers!